Setting the industry standard with a NEW, integrated UNITARY SYSTEM

Designed from the ground up to meet the demands of the cannabis industry, our revolutionary, patented Compressor Wall Technology sets entirely new industry standards for precise room control, reliability, and energy efficiency.

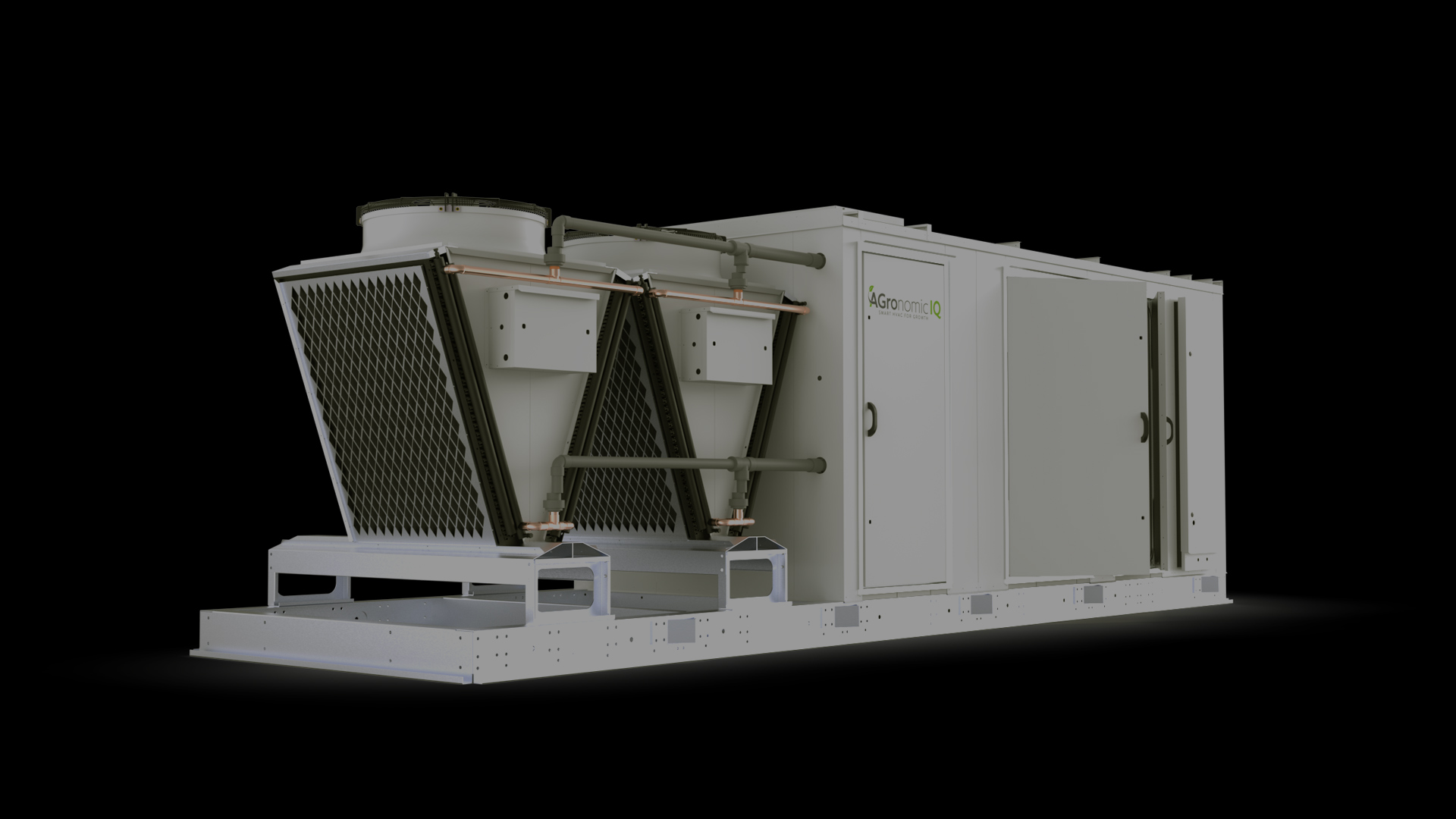

This all-in-one solution is easy and inexpensive to install, has multiple stages of redundancy, weighs up to 50% less than comparable systems, and utilizes a proprietary eco-friendly dry cooler heat exchange system to outperform every other comparable solution.

Revolutionary Design for Grow Rooms

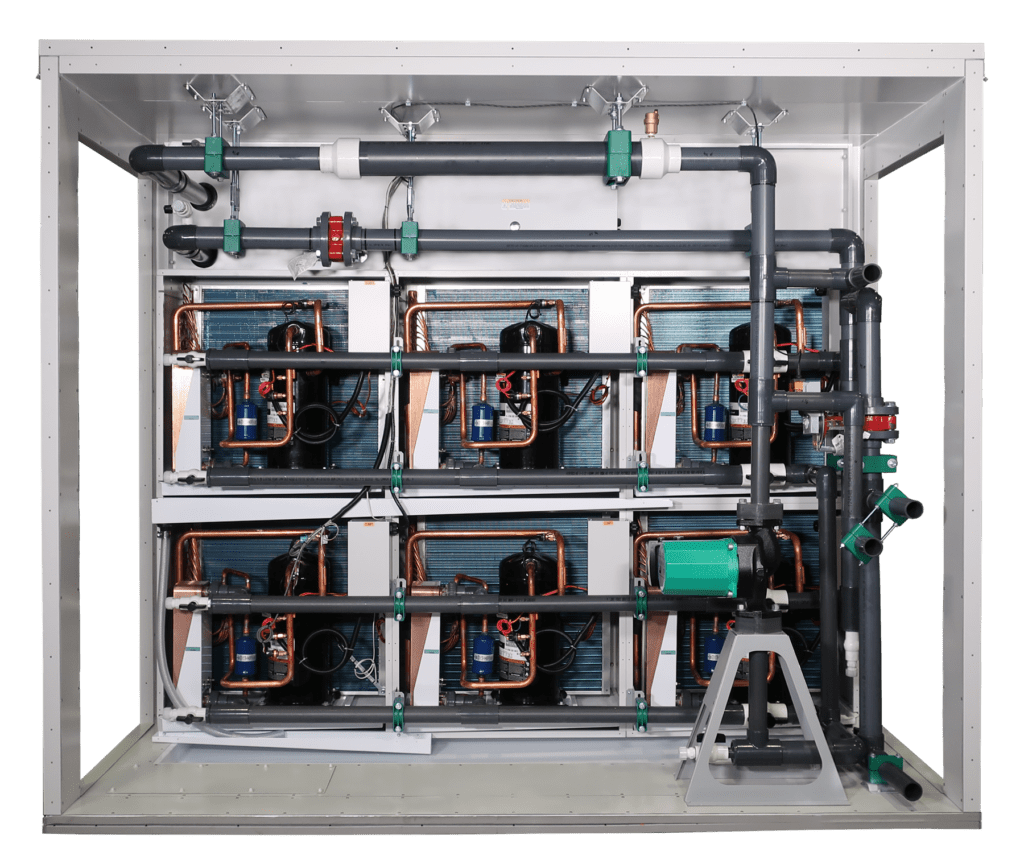

Unlike anything else before it, our groundbreaking Compressor Wall Technology takes a modular, scalable, and redundant approach to dehumidification, heating, and cooling.

It combines multiple compact refrigeration circuits, up to 16 in our larger units, into a powerful Compressor Wall array, delivering up to 32 stages of performance in a unitary solution.

This allows the system to dynamically deliver the exact conditions required for growing cannabis and brilliantly conserve energy in the process. No over drying or over cooling, regardless of plant size or stage of growth – day or night.

The ultimate solution

Combined with our proprietary Dry Cooler heat exchange system, the AGronomic IQ Series Compressor Wall outperforms every other large capacity system in every critical consideration.

CAPACITY RANGES

- Moisture removal: 20 to 730 lbs/hr

- Air handling: up to 44,800 CFM

- Compressor capacity: 10 to 128 tons

- Highlights of the patented Compressor Wall design

- Cost effective, high performance – designed 100% for grow rooms

- A long list of features to learn more about – below!

- A step-by-step walkthrough of the technology, compartment by compartment

- Packaged systems details and benefits – sealed system simplicity, glycol benefits

- Configuration flexibility, exceptional quality components, Internet monitoring

- Compressor modules close up and details, scalable performance, room stability benefits

- Dynamic system response, precision control capability, controls outside of air stream

Features

- Multiple individual compressor modules and multiple fans for built-in redundancy

- Precise dynamic scalable system performance for every stage of growth (up to 32 stages)

- The savings and security of a refrigerant charge that’s less than 10% of traditional equipment

- The convenience of easy, fast, inexpensive plug and play replacement of individual compressor modules with minimal downtime

- The confidence of eco-friendly, water-glycol heat exchange technology that totally prevents the debilitating and expensive cold weather issues of traditional AC heat rejection

- The space efficiency and flexibility of equipment that’s typically 50% the size and weight of comparable capacity equipment

- The ease, efficiency, and cost savings of PVC piping to outdoor condensers

- The peace of mind knowing your Internet-monitored system tracks over 100 parameters and sends automated trouble alerts to warn of potential issues, before they become problems